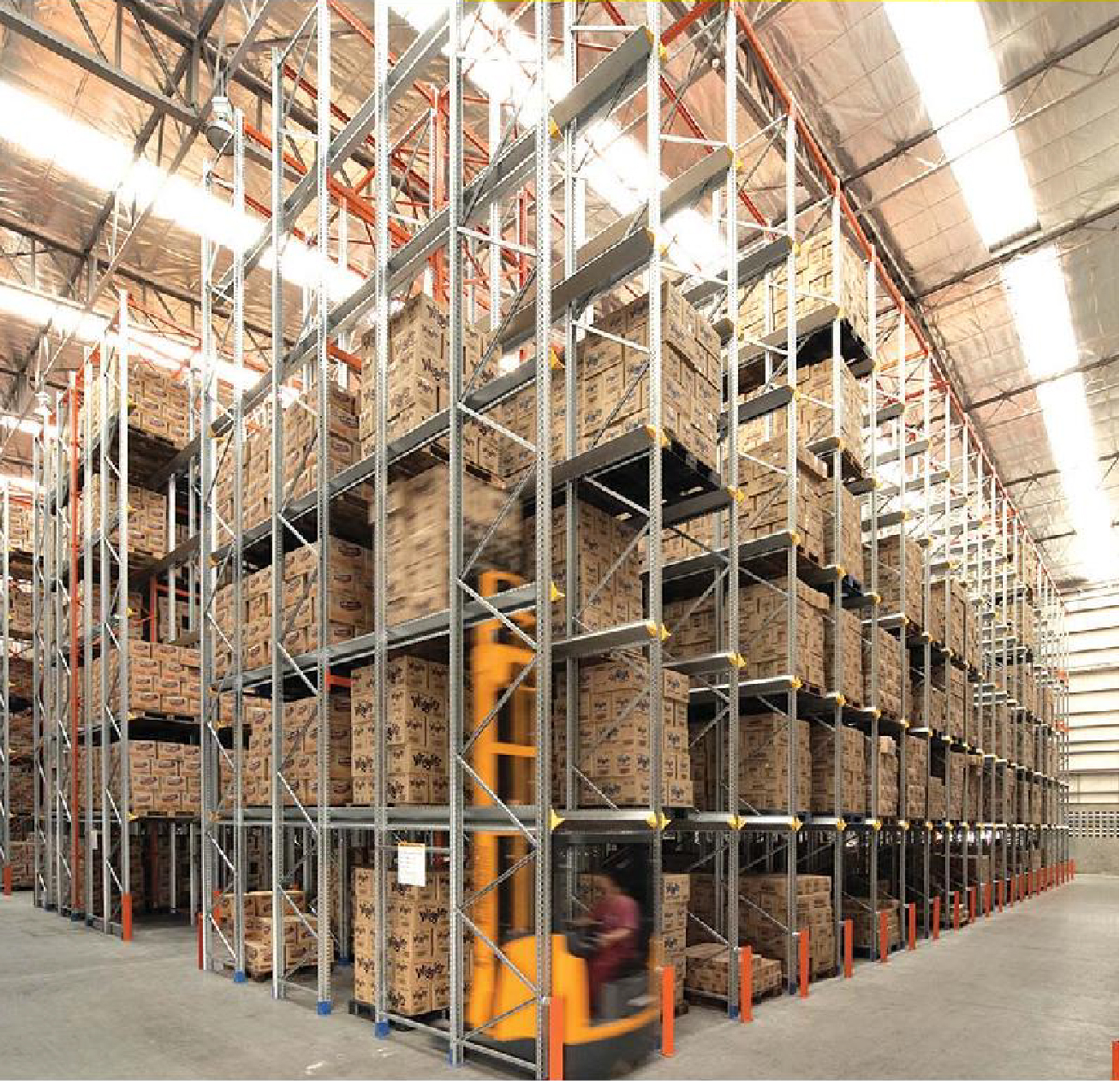

Drive-In Pallet Racking

Drive-In Pallet Racking Systems provide maximum storage capacity using the minimum amount of space. It is particularly suited capacity using the minimum amount of space. It is particularly suited to store very large quantities of of homegeneous products.

Drive-In or Double Access Systems consist of continuous lanes of racking with only a single load and retrieval aisle. Loading and unloading is undertaken by means of counter balance or reach trucks that drive down each lane into the racks. Drive-In racking operates on the basis First-In Last-Out [FILO], therefore it only suites product, which is stored in sufficient volume to require multiple lanes to ensure stock rotation.